PCMC’s recent open houses delivered a deep dive into flexible packaging and folding carton printing trends and innovation

The “Power Packs Live” event at PCMC’s Packaging Innovation Center in Green Bay, WI was packed with education, equipment demos, and networking.

GREEN BAY, Wisconsin – May 18, 2024 -- Paper Converting Machine Company (PCMC), part of BW Converting Solutions, recently held two free information-packed open houses at its state-of-the-art Packaging Innovation Center in Green Bay, Wisconsin, April 23-25. More than 160 people attended the three-day event which focused on both digital printing for flexible packaging as well as digital and flexo printing for the folding carton industry. “We were very pleased with the turnout and quality of information we were able to provide the industry,” said Rodney Pennings, PCMC’s Director of Sales-Print. “The spirit of the Packaging Innovation Center and our Power Packs educational video series is to serve as a resource for print and packaging industry information, demos, trials, and training along with research and development opportunities.”

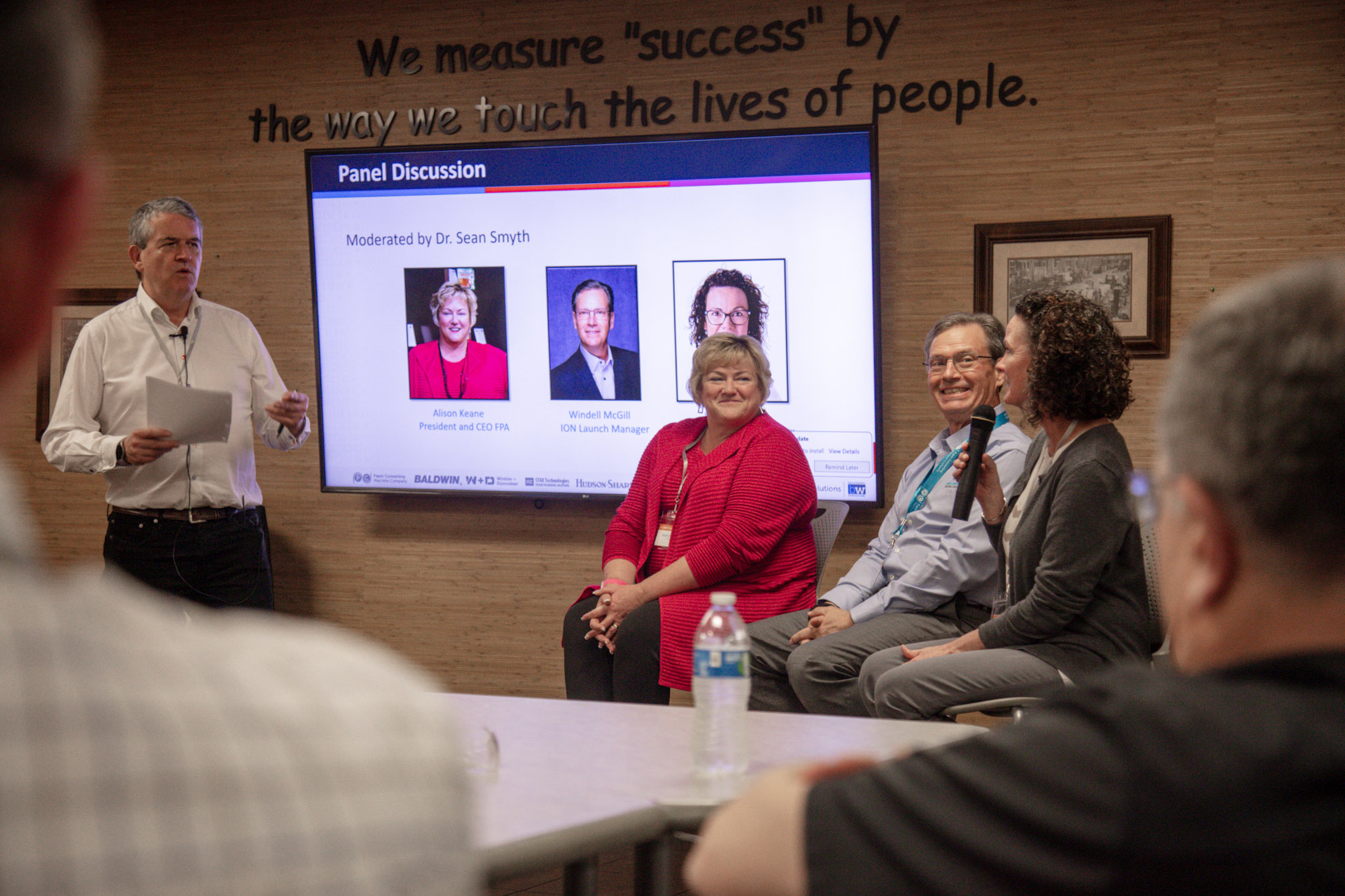

The recent open houses were true to the vision. A wealth of market and trend data, industry analysis, and best practice information was provided by guest speakers from across the globe including Dr. Sean Smyth, industry consultant and analyst, Jason Thelander of Memjet, Alison Keane of the Flexible Packaging Association, Dennis Gignac of BW Papersystems, Sean Hampson and Keith Grimm of Hybrid, Eric Nelson of Xitron and Mary Schilling of Schilling Inkjet Consulting. In addition to guest speakers, PCMC provided up close and personal demonstrations of two exciting new presses.

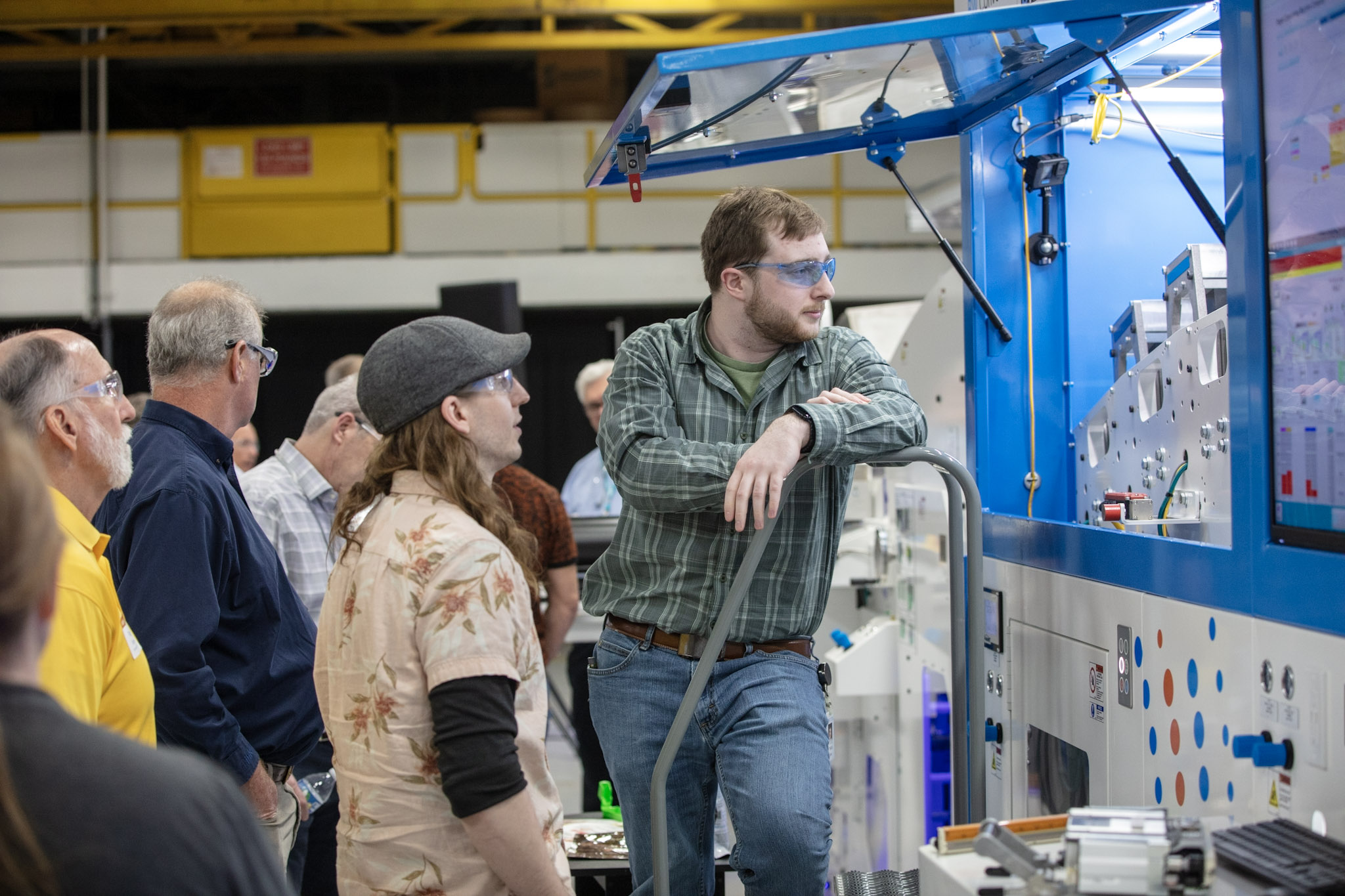

On Tuesday and Wednesday, attendees were able to see the ION hybrid press live in action. The ION highlights the marriage of traditional analog flexographic printing with digital hybrid printing platforms, providing the ability to produce larger digital runs cost competitively. “ION meets market needs for wider, faster printing with highest quality,” says Windell McGill, PCMC ION Launch Manager. “It is designed to handle up to 400 feet per minute with web widths of 36, 42 and 52 inches for paper, film and folding carton.”

The ION is a fully modular system with digital CMYK and flexo print stations that can be custom configured to meet a variety of customer challenges. Jenifer Grace of LaCore Pressworx, the first customer to purchase an ION press, was also on hand to share her experience with the new press. “We’re in the nutraceutical space and our clients are typically start-ups or small influencer-brand product manufacturers. We need the flexibility of short runs and the ability to quickly change from one flavor or ingredient to the next without wasted time or materials,” says Grace. “The ION is going to allow us to meet these needs. In addition, we’re a Texas corporation and the incredible on-site service PCMC provides and the fact that they are here in the states were critical factors in our decision to partner with them.”

On Thursday, attendees were treated to a press-side demonstration of the high-production 59 inch wide, 10+2 color Fusion CI folding carton press. “The Fusion has great energy and time-saving features like automatic drum cleaning and automatic impression setting,“ said Mike Shaw, PCMC Regional Sales Manager. “The Fusion reduces energy usage through low-power-consumption components, design and operation. It offers fast changeovers and lower ink usage,” said Scott Derouin, PCMC Regional Sales Manager. “The Fusion lowers operating costs and provides a quick return on investment and those benefits increase significantly when moving from sheet-fed to web-fed production.”

“We thank everyone who attended our open house event,” said Pennings. “We’re thrilled to be able to share the latest industry information from true industry experts and show-off our amazing new presses in the process.”

ABOUT PAPER CONVERTING MACHINE COMPANY (PCMC)

Paper Converting Machine Company (PCMC), part of BW Converting Solutions, a strategic alliance of resources and services comprised of six industry-leading brands, specializes in the design, manufacture, and service of high-performance converting machinery for the tissue, hygiene, bag converting, and printing industries worldwide. Our comprehensive product offerings include rewinding, laminating, printing, embossing, perforating, folding, and packaging equipment for roll and folded tissue; plastic bag-making equipment, pouch-making equipment, and pre-applied closure solutions for the bag-converting industry; and a complete range of printing presses and laser anilox cleaners, serving the flexible-packaging, prime-label, and carton-converting industries. For more information, visit pcmc.com.

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper-converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $2.5 billion organization with more than 11,000 team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his new book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family. To learn more, go to barrywehmiller.com.