BW Converting to unveil world’s first in-line cleaner for non-stop production of advanced battery foils at Battery Show North America

Automated ‘EPIC’ system by Baldwin maximizes efficiency, ensures safety and slashes costs

More details in booth 6602 at the Battery Show North America, October 7-10 in Detroit, Michigan

GREEN BAY, Wis. — September 3, 2024 — BW Converting will transform the production of advanced battery foils in EPIC proportions with its debut of the world’s first in-line cleaner at the Battery Show North America, October 7-10 at Huntington Place in Detroit, Michigan. Battery manufacturers will get a first look at the groundbreaking Electrode Press Industrial Cleaning (EPIC) System by Baldwin and Corona Pure which can be combined for a superior and cost-efficient solution in cell manufacturing.

The first-of-its-kind EPIC system offers unprecedented automation for cleaning in calender processes, specifically for anode and cathode foil production. Operating at up to 302°F. (150°C), EPIC ensures unmatched surface cleanliness, leading to superior battery foil quality and higher productivity.

This innovative system uses a unique solvent formulated to stand up to high heat to clean the calenders automatically with the machine running. The process takes 2- to 4-minutes, versus 45 minutes in anode and multiple hours in cathode typically required, by eliminating the need for cooling and manual cleaning.

Safety is a top priority with the EPIC System. Fully automated cleaning removes the risks associated with manual handling of hot, turning rollers and hazardous chemicals, creating a healthier work environment. The system uses a special lint-free microfilament cloth that absorbs dirt and fluids without scratching the mirror-polished rollers, ensuring continuous, high-quality production.

EPIC also offers customizable cleaning sequences through a digital touchscreen control panel, allowing the operator to adjust wash cycles, detergent dosage, and more. With features like reduced downtime, minimized waste and improved safety, the EPIC System is designed to maximize efficiency and ensure a smooth, uninterrupted production process. In addition to worker safety, EPIC’s high-precision process eliminates the risk of inferior cleaning that can ultimately lead to batteries catching on fire.

EPIC was engineered by adapting Baldwin’s long-proven Film Cylinder Cleaner for the film extrusion market. It can be provided by OEMs who manufacture calendering units or retrofitted onto existing equipment in giga factories. All that’s required for a retrofit is for eight holes to be drilled where the EPIC unit is attached with a single day required for installation of each calendering unit.

BW Converting has put the EPIC System to the test for the past eight months at three factories where it is running on calenders on a daily basis with flawless results.

“Coming out of a long-term product development program, we – at Baldwin and BW Converting – are excited about the quick success and substantial benefits we see at our early-bird customer base and can’t wait to enhance automation in many more large-scale advanced battery factories,” said Dennis Behnisch, Baldwin Product Line Leader, Surface, Cleaning and Spray.

Corona Pure: Superior Surface Treatment for Advanced Batteries

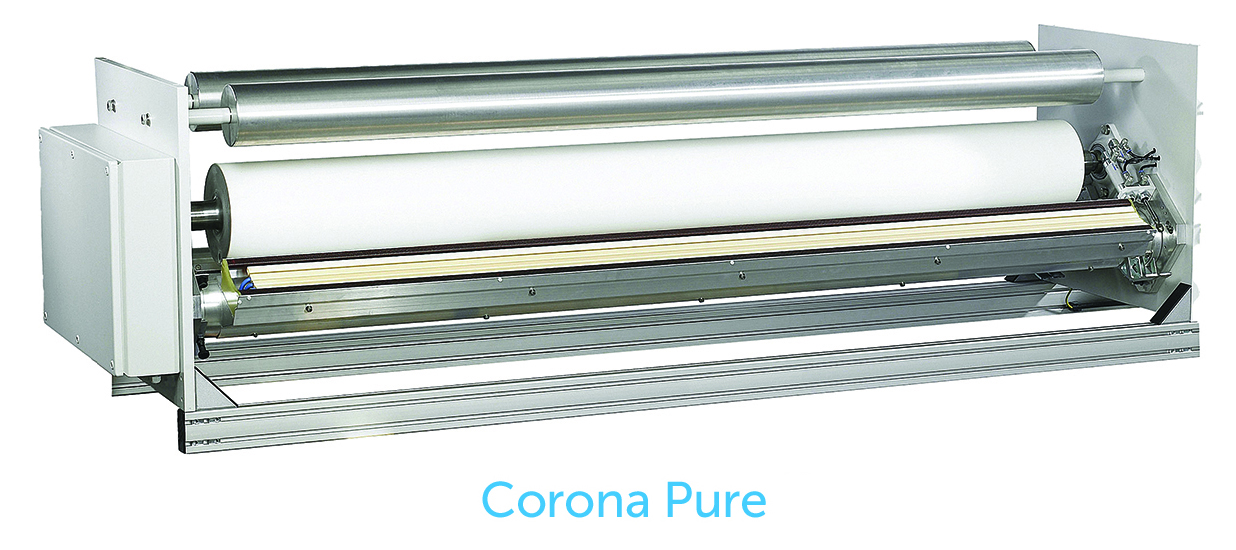

Also, in the spotlight at Battery Show North America will be Corona Pure, which delivers industry-leading efficiency for surface treatment in advanced battery production.

Featuring high-performance, durable, easy-to-handle swiveling electrodes, this system enhances the adhesion of inks, coatings, varnishes, and glues across a wide range of materials. The unique swiveling design ensures long electrode life and easy handling, while the advanced AS-generator minimizes power loss and facilitates seamless external control and data integration.

Corona Pure ensures reliable, efficient performance that improves material bonding and enhances overall production quality and coupled with EPIC, positions battery manufacturers on the forefront of technological innovation for superior battery cells.

“This industry often relies on whatever treatment-state foil-rolls are in, when delivered from their vendor. Placing Corona in line in your battery factory guarantees higher adhesion and better coating performance,” said Dr. Alexander Rau, Baldwin Product Specialist, Corona and Spray.

From paper to plastic, ink to textile, products to packaging, BW Converting changes things for the better. We innovate, design, manufacture, and service precision machinery that unlocks manufacturing opportunities in Tissue, Hygiene, Print, Packaging, Mailing, Textiles and other high-performance Industrial applications. Unifying our product brands Paper Converting Machine Company (PCMC), Winkler + Dünnebier (W+D), Baldwin Technology Co., Hudson-Sharp, STAX Technologies, and Northern Engraving and Machine under one global organization as part of the $3.6 billion Barry-Wehmiller Corporation, we help maximize global industry potential today and tomorrow. To learn more, go to bwconverting.com.

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper-converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $3.6 billion organization with nearly 12,000 team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family. To learn more, go to barrywehmiller.com.