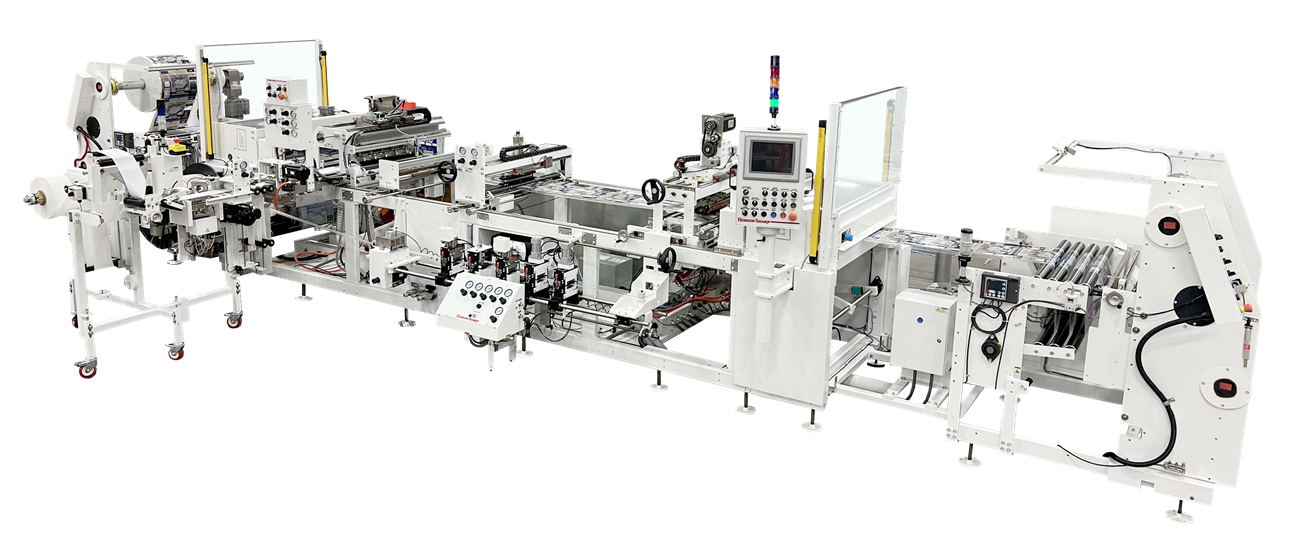

Product Details

Inno-Lok®, BW Converting's Hudson-Sharp brand system, is designed to add innovative resealable technology to flexible bags. Originally introduced in 1997, this patented solution revolutionized zipper application in packaging, enabling the creation of Inno-Lok® Pre-Zippered Film — a roll of pre-zippered film suitable for both barrier and non-barrier applications.

Ideal for industries such as food, beverages and household goods, Inno-Lok® helps businesses deliver bags that extends product freshness, improves storage convenience and enhances consumer satisfaction. Its versatile system seamlessly integrates into existing packaging lines, offering the flexibility to produce both resealable and traditional bags without requiring additional capital investment.

Durable and reliable, Inno-Lok® ensures secure seals to maintain product safety and quality until opened by the consumer. This cost-effective solution helps businesses stay ahead of packaging trends by offering innovative, sustainable and user-friendly options. Enhance your bag-making efficiency and meet growing customer demands with Inno-Lok® today.

Ideal for:

- Vertical FFS gusseted and flat bottom applications

- Horizontal FFS applications

- Pillow pack FFS applications

- Pre-made pouches

- Barrier and non-barrier applications

Requires 3-4 mm clearance between forming collar and fill tube to allow zipper to pass through

Variety of closure options available including:

- Front panel pull or thumb tab

- Bag Top (traditional opposing wall closure)

- Pour & Lok® reclosable pour spout

- ZIP360® wide-mouth opening

INNO-LOK films run comparably to standard non-closure films on conventional FFS equipment.

- Run faster than in-line or on-line transverse closure systems

- No additional equipment needed

- Fewer roll changes needed; film and closure are the same roll

Bag Types:

Pour & Lok®

A resealable pour spout for side gusseted and non-side gusseted packaging.

- Press-to-close, foldable closure is pre-applied to film in the side gusset of the package

- Allows for large openings for scoopable products

- Available as an attachment to our INNO-LOK 1400 machines and pouch machines

Bag Top

.jpg?sfvrsn=30d7980c_1)

Create a cut-to-open package with a reclosable zipper feature with Bag Top pre-applied closures.

- Identical to packages created with in-line systems

- Opposed wall, three-flange closure

- Bag access via cut top or perforation

- Gas barrier applications possible

- Final closure seal is made during the VFFS process

ZIP360®

The wide-mouth opening of the ZIP360 resealable pouch is produced using a pre-applied 360-degree perimeter closure.

- Provides easy access to content via cut top or perforation

- For side-gusseted and non-side-gusseted packages

- Dynamic graphics on all sides for maximum shelf impact

EZ-Stand® Solution

Allow your VFFS packaging to stand up and stand out with pre-applied bottom gussets. In addition to pre-applied closures, the Hudson-Sharp INNO-LOK machine offers the ability to pre-apply bottom gussets to roll stock with EZ-Stand technology EZ-Stand packages are formed using a film web with a pre-applied folded panel. When the package is formed and sealed the panel unfolds to become the bottom of your stand-up bag.

- Use existing VFFS baggers to produce stand-up bags

- Faster fill rates than pre-made stand-up pouches

- Only minor VFFS equipment changes needed

- Simple installation process and minimal operator training

- Supports multiple INNO-LOK closure styles

- Hole punch, tear notches and laser scoring available

- No increase in scrap or waste

- No increase in set-up time

- Offers maximum scheduling flexibility on VFFS equipment

- Minor capital investment with quick return

Front Panel

The reclosable front panel feature combines convenient front panel access to package contents with a resealable zipper.

- Thumb tab or pull tab options

- Wide access with secure closure

Zipper Unwind

- New! Servo-driven unwind

- Frame mounted

- Zipper sealer handles all zipper types

- Servo-driven module

- Quick-change seal bar replacement

- Quiet operation

- Six-position turret zipper receiver for guiding and placement

- Unwind and rewind handles all zipper types

- Dual spindle construction

- VFAC-driven with servo draw roll

- BST edge-guided web

Resources

Technical Specifications

750 1400

| Machine Width | 750 mm / 30 in 1400 mm / 56 in |

| Max. Web Width | 711 mm / 28 in 1370 mm / 54 in |

| Draw Length | 100 - 610 mm / 4 in - 24 in |

| Parental Material | Heat-sealable monolayer or coextruded film or thermoplastic laminations between 50-125 microns thick |

| Min. Package opening | 82 mm / 3.22 in |

| Max. Package Opening | 286 mm / 11.25 in 387 mm / 15.23 in |

| Machine Speed | Up to 150 cpm |

| Standard Electrical | 60 cycle / three-phase, 35 Kva |

| Air: | 2400 l/min |

EZ-Stand

| Bag Width | 101 mm - 355 mm 4 in - 14 in |

| Finished Gusset | 38 mm / 89 mm 1.5 in - 3.5 in |