Product Details

BW Converting's W+D 449 E-COMMERCE machine can produce sustainable, reusable paper mailing bags - specially developed for the needs of online retail.

BW Converting's historic W+D brand has been established in the envelope and mail industry for 110 years and can offer profound expertise in paper processing. As a leading global technology, system solution and service partner in mechanical engineering, BW Converting is your partner for e-commerce shipping thanks to wide-ranging expertise in all relevant production processes.

Mailing Bag Key Facts

- Specially developed for approximately 80 percent of e-commerce shipments

- Up to 2 peel and seal stripes for single and dual-use

- Fingerlift for fast sealing process

- Tear strip with different perforation shapes

Mailing Bag Formats

A wide range of production options from one machine: with or without side gussets, or zero waste - in different formats and flexible in both material and grammage.

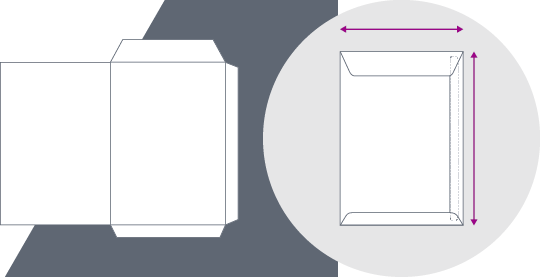

Standard Mailing Bag

WidthMin. 229 mm (9 in) - max. 380 mm (14.9 in)

HeightMin. 305 mm (12 in) - max. 480 mm (18.9 in)

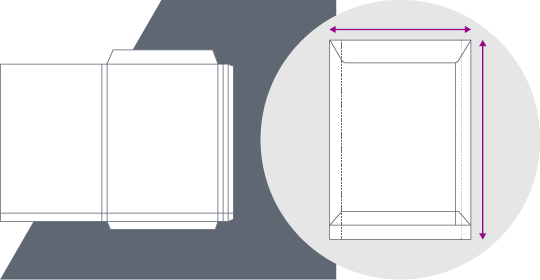

Mailing Bag With Gusset

WidthMin. 229 mm (9 in) - max. 380 mm (14.9 in)

HeightMin. 305 mm (12 in) - max. 480 mm (18.9 in)

Gusset (open)Max. 80 mm (31/8 in)

Zero Waste Mailing Bag

WidthMin. 229 mm (9 in) - max. 380 mm (14.9 in)

HeightMin. 305 mm (12 in) - max. 480 mm (18.9 in)

Gusset (open)Max. 80 mm (31/8 in)

Best Performance for Economical Production

With the W+D 449 E-COMMERCE, BW Converting is building the fastest solution for the complete production of high-quality paper mailing bags. BW Converting's extensive experience in paper processing makes the difference - noticeable in every detail. Different extension stages and a variety of production options, each involving just one pass, which allows maximum flexibility and productivity.

- All-in-one process - from the paper roll to the finished mailing bag

- Maximum speed - up to 300 mailing bags per minute

- Options for Splicer and Bundle Stacker allows highest performance

- Various cut and mailing bag shapes

- Produce a wide range of paper types and weights ranging from 90 - 200 GSM

- 1-4-color flexo printing available

- Production process for high-quality mailing bags, e.g. web tension control

- Applicator for 2 peel and seal strips and 1 tear strip in a single inline process

- Application of peel and seal and tear strip at the end of the process

- Variety of tear strip perforation shapes

- Format-independent cutting sections

- Few format parts required

- Nearly all-toolless format change

- Job settings save options for faster repeat jobs

- Central operation via moveable HMI with fine adjustment options during operation

- Open design for easily visible production process

- Low-noise production operation

- Robust 24/7 W+D design